Accurate Shear Web Cutting

Mark Drela’s technique for accurately cutting balsa shear webs for wing spars

This section of the site contains articles about model construction contributed by our members and anyone else we can cajole into contributing! If you have an idea that you think others might benefit from, please contact us.

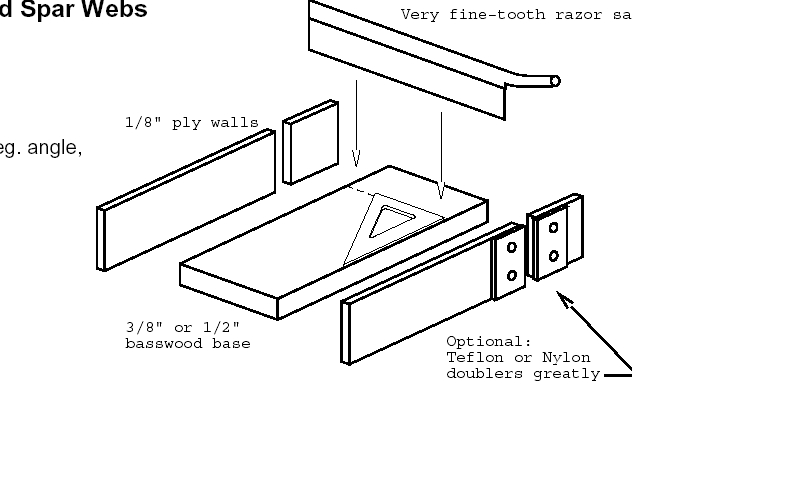

Mark Drela’s technique for accurately cutting balsa shear webs for wing spars

An article by Mark Drela on how to sand accurately - especially useful for wood wings such as those used on Mark’s Apogee HLG

Pete Young’s writeup on how to get all the panels to match up “just right”

Bill Wingstedt’s solution to “how to get those darned wing servos plugged in easily”

Mark Drela’s technique for building aerodynamically clean spoilers in composite wings

Mark Drela’s technique for solid balsa shaped wings, as used in the Apogee HLG and national record winning indoor HLG’s

a quick and easy tip on how to lighten foam wings without fancy tools

Notes by Mark Drela on how to build 3.5-4 gm bagged tails

How to make a hatch that fits just right in a fiberglass fuselage

Darwin Barrie’s neat way to make v-tails removable

A neat trick for aligning v-tails and wings in a flash

Another approach for lightweight vtail and sheet surfaces

… and other sheet surfaces

An easy way to make form-fitting nosecones

A quick way to adjust wing/tail incidence on HLG’s without detaching, shimming and gluing things back together!

Notes by John Schmoll on using carbon fiber pushrods in HLG applications

Some thoughts by Harley on how to use RADS in a molded ship

Mark Drela’s tips on making great, strong, lightweight hinges

Two ways to make sure your hinge points are solidly locked in place and installed with free movement

Coupler ideas for the rotary drive system

Making mini-sockets (couplers) for HLG, Tail Pieces, ETC.

Harley Michaelis’ RADS Linkage Design is an all-internal rotary aileron/flap driver system, leaving no exposed pushrods or control horns while providing positive control.

How to mount micro servos in a minute with practically no added weight, and no tray to build

Silicone hinges are easy, durable and require a little skill to get them the way you want them.

How to prevent the surfaces from pulling out of your dreamboat at an “inopportune time”

NAME IT! Did you just finish a new plane? Ready to take it out the field and show off your work and maybe put in a couple of trim flights? One thing is missing - you need a name or numbers on it! Here is an inexpensive and quick way to get that “Custom” name on your plane at home, with your own hands. The materials used are not fuelproof, so they can only be used on electric models, gliders, boats, cars and make great window signs for your van.

Thinned dope is the classic way to attach tissue. There are other alternatives that some people prefer. A popular way that is pretty easy is to use glue stick. Its very simple to simply spread the glue on the perimeter of the area you are covering. If you want to stretch out wrinkles you can simply moisten the edge and the glue releases again. When you dope it the glue the adhesion is water proof.

A detailed writeup on Dave Wenzlick’s technique for rugged EPP sloper covering - especially for those locales with really hot temperatures where 3M77 lets go

How to get fiberglass parts ready for a successful finish

A writeup on hazards of carbon fiber to watch out for

I don’t know how big the pin holes are that you guys are trying to fill, I have always used an inexpensive product called 3M Acryl-Green Spot Putty product number 051144-05960 with good success. Apply it with just a soft plastic squeegy, it dries fast and sand with 600 wet paper, prime and sand and paint, and wala! pin holes bye bye! This is my 10 centavos worth.

A great synopsis of how to apply fiberglass smoothly, lightly and consistently

Read this important note about latex vs. vinyl gloves when working with epoxy!

The instructions that come with MicaFilm covering, and many kits, suggest that you should apply the BalsaLoc (water-based) or BalsaRite (solvent-based) adhesive directly to the wood structure that you will be covering. This does provide adhesion, but has a couple of bad side effects: The wood absorbs an outrageous amount of the adhesive, adding unnecessary weight to the model Thin wood sections will warp very noticeably from being “wetted” on one surface (this can be somewhat handled by wetting both sides at the same time, but this can be tricky and adds weight as mentioned above) So the easy answer is, don’t apply the adhesive to the structure!

A great set of tips and ideas on all manner of sanding adventures!

A tip by Ron Fikes about how to cut out smooth wood parts without a scroll saw

Jody Vogel’s notes on how to build a Zagi-THL at well under 10 ounces complete

A table in web, PDF and Excel form, with weights in various units of measurement